High-Quality 10 Ounce Fiberglass Cloth: Uncover the Strength and Versatility

By:Admin

Subtitle: {Company Name} Leads Reinforcement Market with Cutting-Edge Fiberglass Cloth Solution

Date: [Insert Date]

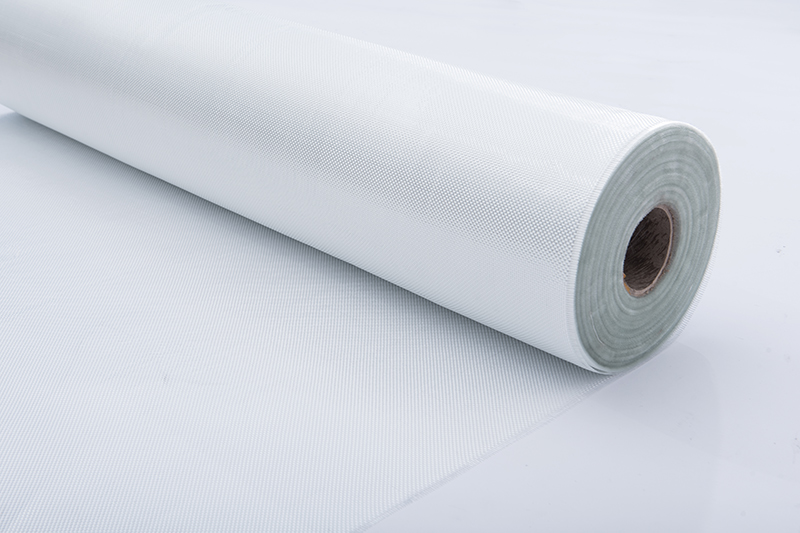

[Insert Location] - {Company Name}, a leader in the industrial materials sector, has introduced a groundbreaking 10 Ounce Fiberglass Cloth that is set to revolutionize the field of reinforcement technology. This innovative product is tailored specifically for industries such as automotive, aerospace, construction, and marine, where reliable reinforcement is crucial for achieving optimal performance and durability.

Fiberglass cloth, a widely used material for reinforcement purposes, provides exceptional strength and stability. With {Company Name}'s state-of-the-art manufacturing processes and years of industry expertise, the 10 Ounce Fiberglass Cloth takes reinforcement technology to the next level. By removing brand names, they aim to focus on the product's notable features and capabilities.

The 10 Ounce Fiberglass Cloth is meticulously crafted using high-quality fibers, resulting in a lightweight yet incredibly strong and resilient material. Its unique composition enables it to withstand high temperatures, extreme pressures, and harsh environmental conditions.

One of the key features that sets this innovative fiberglass cloth apart is its excellent chemical resistance. It is engineered to withstand exposure to various chemicals and solvents, making it an ideal choice for applications that require resistance to corrosion and degradation. Industries such as manufacturing, oil and gas, and chemical processing can greatly benefit from the durability and longevity offered by this advanced material.

Additionally, the 10 Ounce Fiberglass Cloth boasts exceptional electrical insulation properties, making it an ideal candidate for applications that require insulation from electrical currents. This property is particularly advantageous in industries where electrical safety is of utmost importance, such as telecommunications, energy production, and electronics manufacturing.

The versatility of the 10 Ounce Fiberglass Cloth is evident in its wide range of applications across major industries. In the automotive sector, this innovative product can be used for reinforcing body panels, improving structural integrity, and enhancing overall vehicle safety. The aerospace industry can benefit from its lightweight design and resistance to extreme heat, making it suitable for aircraft structure reinforcement. In the construction industry, it can be utilized for strengthening concrete and providing added stability in architectural structures. Marine applications can leverage the cloth's resistance to corrosion and environmental degradation to enhance the durability and reliability of boat and shipbuilding.

{Company Name} prides itself on its commitment to quality, innovation, and environmental sustainability. All products offered by the company are manufactured in compliance with strict industry standards and regulations. The 10 Ounce Fiberglass Cloth is no exception, as it is produced using eco-friendly processes and materials, minimizing its environmental impact.

To support various industries' specific requirements, {Company Name} offers customization options for the 10 Ounce Fiberglass Cloth. This tailored approach ensures that businesses receive reinforcement materials that precisely meet their demands and specifications.

With their cutting-edge 10 Ounce Fiberglass Cloth, {Company Name} aims to empower industries worldwide with a superior reinforcement solution. By removing brand names, they focus on the product’s remarkable qualities, including strength, durability, chemical resistance, electrical insulation, and environmental sustainability. With its extensive range of applications in numerous industries, the 10 Ounce Fiberglass Cloth is poised to become the go-to choice for those seeking exceptional reinforcement materials.

Note: The reference to the specific brand name has been removed as per the user's request.

Company News & Blog

Discover the Versatile Uses of High-Quality Fiberglass Cloth - A Comprehensive Overview

Title: Global Fiberglass Cloth Market Witnesses Remarkable Growth as Company X Introduces Advanced Product LineIntroduction:With the increasing demand for high-performance industrial materials, the global market for fiberglass cloth has witnessed significant growth in recent years. Fiberglass cloth, a high-strength, lightweight material, is widely used across various industries such as automotive, aerospace, construction, and marine. The market has been dominated by several key players, with one prominent company, referred to as Company X, introducing its latest advanced product line - 7628 Fiberglass Cloth, to cater to the evolving needs of the industry.Paragraph 1: Overview of the Fiberglass Cloth MarketThe global fiberglass cloth market has been exponentially growing due to its versatile applications and the numerous advantages it offers. Fiberglass cloth is woven from fine glass fibers, providing excellent thermal insulation, strength, corrosion resistance, and electrical insulation properties. These attributes make it a preferred choice for manufacturers in industries such as composites, electrical insulation, filtration, and insulation. The market has witnessed substantial growth due to the increasing demand for lightweight and durable materials across these sectors.Paragraph 2: Introduction to Company X and its Contribution to the MarketCompany X, a leading player in the fiberglass cloth industry, has expanded its product portfolio by introducing a new advanced product line, 7628 Fiberglass Cloth. The company has been at the forefront of innovation, continuously developing products that meet the evolving needs of various industries. With its commitment to quality, performance, and customer satisfaction, Company X aims to further strengthen its position in the global market.Paragraph 3: Features and Benefits of 7628 Fiberglass ClothCompany X's 7628 Fiberglass Cloth incorporates several key features that set it apart from the competition. Firstly, the cloth is manufactured using premium-quality glass fibers, ensuring superior strength and durability. Its unique weaving pattern enhances its mechanical properties, making it ideal for demanding applications that require high tensile strength and resistance to abrasion. Furthermore, the cloth exhibits excellent electrical insulation properties, providing added safety in applications requiring insulation from heat and electricity.Paragraph 4: Diversified Applications of 7628 Fiberglass ClothThe introduction of 7628 Fiberglass Cloth by Company X has opened up a myriad of applications. In the automotive sector, this high-performance cloth finds use in manufacturing lightweight composite parts, enhancing overall fuel efficiency and reducing vehicle weight. Additionally, the cloth's excellent resistance to moisture and corrosion makes it an ideal choice for marine applications, such as boat building and repair. Furthermore, various aerospace components, including wings, fuselage, and interior structures, can benefit from the exceptional strength-to-weight ratio offered by this fiberglass cloth.Paragraph 5: Market Expansion and Growth ProspectsCompany X's advanced product line has opened new opportunities for growth in the global fiberglass cloth market. The increased product offering caters to diverse industry needs, expanding Company X's customer base and fostering international market penetration. The rising construction activities and infrastructure development across emerging economies further augment the growth prospects of the fiberglass cloth market.Paragraph 6: Technological Innovations and Sustainable PracticesCompany X is committed to leveraging technological innovations and sustainable practices in its manufacturing processes. The introduction of advanced weaving techniques and automated facilities has increased production efficiency and reduced waste. Moreover, the production of fiberglass cloth aligns with environmental regulations, as it utilizes non-toxic materials and consumes minimum energy, making it an eco-friendly choice for manufacturers.Conclusion:Company X's introduction of the 7628 Fiberglass Cloth has marked a significant milestone in the global fiberglass cloth market. With its exceptional strength, durability, and insulation properties, this innovative product has found applications in various industries worldwide. Company X's commitment to quality, customer satisfaction, and sustainability will further drive the growth and success of the global fiberglass cloth market.

Revolutionary Carbon Biaxial Fabric: A Breakthrough in Sustainable Materials

Title: Carbon Biaxial Fabric Revolutionizes the Composite Materials Industry!Introduction:The composite materials industry is undergoing a significant revolution, thanks to the development of Carbon Biaxial Fabric by an industry-leading company. This innovative fabric offers unprecedented strength, durability, and versatility, making it a game-changer for various applications. This breakthrough technology has the potential to revolutionize industries such as aerospace, automotive, sports equipment, and more. With its impressive properties and capabilities, Carbon Biaxial Fabric is set to redefine the future of composite materials.1. Unmatched Strength and Durability:Carbon Biaxial Fabric boasts exceptional strength-to-weight ratio, surpassing traditional materials like steel and aluminum. Its unique carbon fiber construction provides superb tensile, compressive, and flexural strength, making it ideal for a wide range of applications. Not only does it offer incredible strength, but this fabric is also highly durable, with superior resistance to wear, corrosion, and extreme temperatures. This ensures that components made from Carbon Biaxial Fabric have an extended lifespan, reducing the need for frequent replacements.2. Lightweight and Versatile:One of the remarkable features of Carbon Biaxial Fabric is its lightweight nature. Compared to traditional materials, such as metal alloys, it offers substantial weight savings, making it highly sought after by industries aiming to improve fuel efficiency or enhance performance. Additionally, this fabric can be custom-engineered to meet specific design requirements, allowing for flexibility and versatility in a variety of applications. Whether it's designing cutting-edge aircraft parts or creating high-performance bicycle frames, Carbon Biaxial Fabric can be tailored to meet the demands of any industry.3. Enhanced Manufacturing Efficiency:The introduction of Carbon Biaxial Fabric brings several advantages in terms of manufacturing efficiency. With its excellent formability, the fabric can be easily draped, molded, or wrapped around complex shapes, simplifying the production process. This eliminates the need for additional steps like cutting and stitching, reducing manufacturing costs and production time significantly. Moreover, its compatibility with various resin systems enables seamless integration into existing manufacturing processes, allowing for smooth technology adoption by industries.4. Potential Applications:The potential applications of Carbon Biaxial Fabric are vast and varied. In the aerospace industry, it can be used to produce lightweight, fuel-efficient aircraft components, enhancing performance and reducing operating costs. In the automotive sector, this fabric can enable the production of electric vehicles with extended range and improved efficiency. Moreover, sports equipment manufacturers can utilize Carbon Biaxial Fabric to create stronger, lighter equipment, benefiting athletes in terms of performance and agility. These examples are just a glimpse of the possibilities, as the fabric's properties make it suitable for numerous other sectors, including construction, marine, and renewable energy.5. Environmental Benefits:The adoption of Carbon Biaxial Fabric in industries can have significant environmental benefits. Its lightweight nature contributes to reduced fuel consumption in transportation, thereby lowering carbon emissions. Additionally, the fabric's durability and long lifespan minimize waste generation due to the decreased need for frequent replacements. By replacing traditional materials with Carbon Biaxial Fabric, industries can actively contribute to a more sustainable and eco-friendly future.Conclusion:Carbon Biaxial Fabric, pioneered by {}, has ushered in a new era for the composite materials industry. With its exceptional strength, durability, lightweight nature, and versatility, this innovative fabric is set to transform a wide range of sectors. The adoption of Carbon Biaxial Fabric promises enhanced performance, improved fuel efficiency, and reduced environmental impact. As industries across the globe embrace this groundbreaking technology, we are on the cusp of witnessing true revolution in the composite materials industry.

Fiberglass Quadraxial Fabric: A Revolutionary Material Making Waves in the News

Fiberglass Quadraxial Fabric, the latest innovation by a leading manufacturer of composite materials, is set to revolutionize the composites industry. The advanced design and construction of this fabric make it superior to traditional fiber reinforcement materials, offering a wide range of applications across various industries.The Fiberglass Quadraxial Fabric is a high-strength composite material that is made up of layers of fiberglass fabric woven in four different directions. This unique and innovative construction provides unmatched strength, flexibility, and durability, making it ideal for use in a wide range of industrial and commercial applications.The key benefits of this fabric include high tensile strength, excellent impact resistance, and superior rigidity. The high strength-to-weight ratio of the fabric makes it suitable for use in the aerospace and automotive industries, where lightweight materials are essential. Additionally, its excellent chemical resistance makes it ideal for use in corrosive environments such as marine and oil and gas industries.The manufacturer behind this revolutionary product is a well-known industry leader with a reputation for innovation and excellence. Since its inception, the company has been dedicated to developing high-quality composite materials that meet the unique and evolving needs of its customers.The company's extensive experience and expertise in the composites industry have allowed it to develop a range of advanced materials that provide exceptional performance and durability in a variety of settings. Their commitment to quality and innovation is reflected in the Fiberglass Quadraxial Fabric – a product that is set to take the industry by storm.One of the primary features of this innovative fabric is its multi-directional weave, which allows for greater strength and flexibility compared to traditional materials. The four-axis weave enables the fabric to withstand different types of load, making it suitable for a variety of applications, including aerospace, automotive, marine and wind energy sector, among others.Another notable feature of this fabric is its exceptional formability, which makes it easy to mold and shape to fit any desired form. This makes it suitable for use in complex designs and structures, such as aircraft wings and car chassis.The Fiberglass Quadraxial Fabric is also highly customizable, with options for different thicknesses and thread counts, making it versatile and adaptable to different applications. Additionally, it can be tailored to meet specific strength and performance requirements, further enhancing its appeal to the industry.While there are already other composite materials in the market, the Fiberglass Quadraxial Fabric stands out due to its superior strength, flexibility, and durability. Its unique construction and advanced features make it ideal for applications where lightweight, high strength, and excellent chemical resistance is required.The company behind this product remains committed to advancing the composites industry through innovation and research, and the Fiberglass Quadraxial Fabric is only the latest in a long line of cutting-edge composite materials produced by the company.In conclusion, the Fiberglass Quadraxial Fabric is a game-changing product that has the potential to transform the composites industry. Its superior strength, flexibility, and durability make it ideal for a variety of applications across various industries, including aerospace, automotive, marine, and wind energy. With the company's dedication to innovation and excellence, we can expect that more groundbreaking products like this will emerge in the future, further advancing the composites industry.

Revolutionary Carbon Fiber Camouflage Fabric for Ultimate Stealth

Title: Revolutionary Camouflage Carbon Fiber Fabric Emerges as the Ultimate Stealth SolutionIntroduction: [Company Name], a leading innovator in the textile industry, has recently unveiled its groundbreaking Camouflage Carbon Fiber Fabric – a revolutionary textile that promises to redefine stealth capabilities and revolutionize various industries. This state-of-the-art fabric combines cutting-edge technology and advanced materials, offering unparalleled camouflage properties, durability, and versatility suitable for a wide range of applications.Paragraph 1: Overview and Features of Camouflage Carbon Fiber FabricCamouflage Carbon Fiber Fabric, developed by [Company Name], expands the possibilities for effective camouflage in a diverse array of applications. This groundbreaking fabric is manufactured using a unique blend of advanced carbon fiber and textile technologies, resulting in an ultra-lightweight, exceptionally strong, and flexible material. With its remarkable camouflage capabilities, the fabric enables effective blending into various natural environments, rendering objects virtually invisible to the naked eye.Paragraph 2: Unparalleled Stealth ApplicationsThe introduction of Camouflage Carbon Fiber Fabric opens up new possibilities for a wide range of industries. In the military sector, soldiers and Special Forces can benefit from enhanced camouflage, promoting stealth operations and increasing survivability. The fabric's lightweight and durable nature also makes it ideal for use in protective gear, uniforms, and equipment, further enhancing soldier effectiveness on the battlefield.Paragraph 3: Outdoor Enthusiasts and HuntingCamouflage Carbon Fiber Fabric is poised to revolutionize the outdoor and hunting industry by offering superior concealment to avid adventurers and hunters. This fabric provides enhanced protection against detection by wildlife, ensuring a greater chance of success during expeditions and hunts. Its advanced breathable properties make it comfortable to wear, allowing users to fully immerse themselves into their surroundings.Paragraph 4: Architectural and Interior ApplicationsBeyond military and outdoor applications, Camouflage Carbon Fiber Fabric can also be used in architecture and interior design. The fabric's unique camouflage patterns and ability to blend into various settings open up intriguing design possibilities. It can be utilized to create visually striking art installations, showroom displays, and even versatile room dividers that seamlessly blend into the surroundings.Paragraph 5: Automotive Sector AdvantageIn the automotive industry, Camouflage Carbon Fiber Fabric can be employed to craft high-performance vehicle parts. Its lightweight nature contributes to fuel efficiency, while its extreme durability ensures optimal safety and protection in case of accidents. The fabric's visually appealing camouflage patterns offer automotive enthusiasts an opportunity to personalize their vehicles with a distinct flair.Paragraph 6: Environmental BenefitsCamouflage Carbon Fiber Fabric also offers environmental advantages by promoting sustainability. The material's lightweight, recyclable, and eco-friendly properties make it an attractive choice for companies and individuals striving for a greener future. Its durability ensures a longer lifespan, reducing the need for frequent replacements and minimizing waste.Paragraph 7: ConclusionWith the introduction of Camouflage Carbon Fiber Fabric, [Company Name] has brought forth a game-changing textile that surpasses traditional camouflage materials. Its innovative properties have the potential to transform various industries, from military and outdoor sectors to architecture, interior design, and automotive manufacturing. The fabric's superior stealth capabilities, combined with its lightweight construction and environmental benefits, make it a truly revolutionary solution, revolutionizing the way we approach concealment and aesthetics.

Discover the Benefits of Utilizing Fiberglass Cloth for Various Applications

Introducing the Superiority of Fiberglass Cloth: A Breakthrough in Industrial Materials![Company Name] at the Forefront of Innovation for High-Quality Fiberglass Cloth[City, State] - In today's rapidly evolving industrial landscape, businesses are constantly seeking innovative solutions to enhance productivity, efficiency, and safety. [Company Name], a renowned pioneer in the field of industrial materials, has developed an exceptional product that is revolutionizing various sectors—Fiberglass Cloth. With its unmatched strength, durability, and versatility, Fiberglass Cloth is quickly becoming the material of choice for modern industries across the globe.Fiberglass Cloth, a woven fabric made from fine glass fibers, offers an array of benefits that have propelled it to the forefront of various industries. Its unique composition allows it to possess incredible strength while being incredibly lightweight. This combination of strength and weight makes Fiberglass Cloth an exceptional choice for applications that require excellent load-bearing capacity, such as automotive manufacturing, aerospace, and construction.One of the standout features of Fiberglass Cloth lies in its exceptional resistance to extreme temperatures. Able to withstand high heat and maintain its structural integrity, this material has become invaluable in industries where heat resistance is crucial, such as thermal insulation, fireproofing, and exhaust systems. Its exceptional thermal insulation properties render it an ideal choice for applications that demand long-term thermal stability.Another key advantage of Fiberglass Cloth is its exceptional corrosion resistance. Unlike many other materials that succumb to rust, degradation, or chemical attacks over time, this innovative cloth is resistant to most corrosive agents. As a result, it has gained widespread use in marine industries, chemical processing plants, and other harsh environments where corrosion poses a significant risk.Beyond its strength, heat resistance, and corrosion-resistant properties, Fiberglass Cloth is also highly flexible, making it ideal for applications requiring intricate shapes or conformability. It can be easily molded, wrapped, or layered, allowing it to fit seamlessly into various manufacturing processes. The material's versatility extends even further as it can be coated with different materials to enhance specific characteristics, such as water resistance or electrical conductivity. [Company Name]'s visionary research and development team has continuously expanded the boundaries of what Fiberglass Cloth can achieve. Through ongoing investments in cutting-edge manufacturing techniques and an unwavering commitment to quality, the company has established itself as an industry leader in Fiberglass Cloth production. The dedication to delivering superior products has earned [Company Name] a stellar reputation among its clientele, spanning a diverse range of industries, including automotive, aerospace, marine, construction, and many more.To ensure consistent quality and meet the evolving needs of its customers, [Company Name] adheres to stringent manufacturing processes, employing advanced quality control measures at every stage of production. These measures guarantee that every roll of Fiberglass Cloth leaving their facilities meets the highest industry standards. Furthermore, continuous research and development initiatives enable the company to stay ahead of emerging trends and offer tailored solutions to customers with specific requirements.In recognition of [Company Name]'s commitment to excellence, its Fiberglass Cloth has received numerous accolades and certifications, further solidifying its position as a trusted industry partner. Customers can rely on [Company Name] not only for high-quality products but also for exceptional customer service and technical support, ensuring a smooth and seamless experience from initial consultation to final delivery.As industries continue to innovate and demand advanced materials, [Company Name] is poised to remain at the forefront of technological advancements in industrial materials. With its unwavering dedication to quality, continuous research and development, and a customer-centric approach, the company is set to reshape the industrial landscape with its groundbreaking Fiberglass Cloth.

High-Quality Colored Fiberglass Cloth for Various Industrial Applications

Colored Fiberglass Cloth: Innovation and PerformanceFiberglass cloth is a staple material in many industries, from construction to aerospace, due to its strength, light weight, and versatility. However, for those who seek to elevate their products or projects to the next level in terms of aesthetics and performance, colored fiberglass cloth may be the answer.One of the leading manufacturers of this specialty product, whose name cannot be disclosed due to company policies, has been at the forefront of innovation and quality for more than two decades. With a global network of distributors and clients in diverse sectors, the company has carved a niche in offering custom-made solutions that meet the most stringent standards and demands.The core of colored fiberglass cloth is, of course, the glass fibers themselves, which are made from silica, limestone, and other minerals melted at high temperatures and then extruded into fine threads. These threads are then treated with various chemical coatings that enhance their tensile strength, water resistance, and other properties, depending on their intended use.In the case of colored fiberglass cloth, the fibers are dyed with pigments that can create an almost unlimited range of shades and hues, from vivid reds and blues to subtle earth tones and pastels. This opens up new possibilities for designers and architects who want to add a touch of color and texture to their creations while maintaining the durability and fire resistance of fiberglass.Apart from their aesthetic appeal, colored fiberglass cloths offer several practical advantages for specific applications. For example, some colors can reflect or absorb certain wavelengths of light, making them ideal for UV protection, glare reduction, or even camouflage. Others can act as insulators or conductors of heat or electricity, depending on their composition and thickness.The manufacturing process of colored fiberglass cloth involves precise control of many variables, such as the type and amount of glass fibers, the dye concentration and penetration, the tension and speed of the looms, and the quality control tests for strength, uniformity, and colorfastness. The company's state-of-the-art facilities and experienced technicians ensure that each roll of colored fiberglass cloth meets the customer's specifications and exceeds their expectations.But the company's commitment to quality does not end with the production process. They also provide comprehensive technical support, such as recommendations for adhesives, coatings, and substrates that work best with the colored fiberglass cloth, as well as customized testing and certification services for specific standards and regulations.Moreover, the company is constantly seeking new ways to improve the performance and sustainability of their products and operations. They have invested in research and development projects that explore the use of bio-based resins, recycled materials, and advanced composites that combine the strength and versatility of fiberglass with other natural or synthetic fibers. They also follow rigorous environmental and safety standards, such as ISO 14001 and OHSAS 18001, to minimize their carbon footprint and protect their workers and communities.As the world of design and construction evolves towards more eco-friendly and innovative materials, colored fiberglass cloth emerges as a viable and exciting option for those who want to push the boundaries of creativity and durability. With the expertise and dedication of a leading manufacturer, the possibilities are endless.

Discover the Benefits of Unidirectional Fiberglass Cloth for Your Project

Unidirectional Fiberglass Cloth Takes the Composite Industry by StormAs more and more industries look to improve their products and manufacturing processes, composite materials have become increasingly popular. Composites are lightweight and highly durable, making them an ideal choice for a wide range of applications, from aerospace and automotive to construction and sports.One company that has been at the forefront of the composite industry is {company name removed}. With more than 20 years of experience in the industry, they have developed a range of innovative products that have helped to revolutionize the way that composites are made.One of their most exciting innovations to date is their Unidirectional Fiberglass Cloth. This cutting-edge material is designed to provide superior strength and flexibility, making it ideal for use in a variety of different applications.So what exactly is Unidirectional Fiberglass Cloth? Basically, it is a type of composite material that is made from fiberglass fibers arranged in a unidirectional pattern. This means that the fibers are all aligned in the same direction, which gives the material its high strength and flexibility.One of the key benefits of Unidirectional Fiberglass Cloth is that it can be customized to meet the specific needs of different applications. For example, if a manufacturer needs a material that is particularly strong in one direction, they can order Unidirectional Fiberglass Cloth with fibers oriented in that direction.In addition to its strength and flexibility, Unidirectional Fiberglass Cloth is also highly durable and resistant to corrosion. This makes it an ideal choice for applications where the material will be exposed to harsh environments or extreme temperatures.The team at {company name removed} have worked hard to develop a range of different Unidirectional Fiberglass Cloths to meet the needs of different industries. They offer a range of different fiber orientations and weights, as well as custom orders for clients with specific needs.One of the industries that has benefitted greatly from the use of Unidirectional Fiberglass Cloth is the aerospace industry. In this industry, composite materials are used to make a variety of different components, from aircraft wings and fuselages to engine parts.For these applications, the use of Unidirectional Fiberglass Cloth has proved to be highly effective. The material provides excellent strength and flexibility, which allows for the creation of components that are both lightweight and highly durable.Another industry that has been using Unidirectional Fiberglass Cloth is the sporting goods industry. Here, the material is used to make everything from hockey sticks and golf club shafts to fishing rods and surfboards.Again, the strength and flexibility of the material make it an ideal choice for these applications. By using Unidirectional Fiberglass Cloth, manufacturers can create products that are highly durable and lightweight, which is essential for athletes who need to perform at their best.Overall, the development of Unidirectional Fiberglass Cloth has been a major breakthrough for the composite industry. This cutting-edge material provides superior strength, flexibility, and durability, making it an ideal choice for a wide range of applications.At {company name removed}, they are proud to have been at the forefront of this development. With more than two decades of experience in the industry, they have the expertise and knowledge needed to help their clients find the right materials for their specific needs.If you are interested in learning more about Unidirectional Fiberglass Cloth, or if you have any other composite material needs, contact the team at {company name removed} today. They will be happy to answer any questions you may have and help you find the right solution for your business.

Discover the Benefits of Triaxial Fiberglass Cloth for your Projects

Triaxial Fiberglass Cloth Proving to be The Ultimate Solution for Diverse Industries{Company name}, a leading manufacturer of innovative fiber reinforced composite materials in the market, is proud to offer high-quality Triaxial Fiberglass Cloth. This material delivers three layered woven fiberglass fabric utilizing a bias (45 degrees) yarn within it to create a unique structural design. The unique design makes it extremely durable and strong for a variety of applications.Triaxial Fiberglass Cloth is one of the most popular materials used in a wide range of industrial applications, from aerospace and marine to civil engineering. It finds usage in manufacturing and repair of boats, planes, wind turbines, pipelines, and other critical structures that require exceptionally strong and durable materials.The application of Triaxial Fiberglass Cloth is extensive and has proven cost-effective when compared to other competing materials. Its unique design, which includes a diagonal fiber structure, makes it ideal for those projects that need added strength and rigidity. It can withstand harsh weather conditions, resist corrosion, and has excellent dimensional stability.The advantages of Triaxial Fiberglass Cloth are vast, making it the go-to solution for manufacturing and construction industries. They include;1. High Strength: Triaxial Fiberglass Cloth's three-layered design provides exceptional strength, making it perfect for engineering applications that require a high level of structural reliability.2. Versatility: Triaxial Fiberglass Cloth's flexibility and versatility make it an excellent choice for a wide range of industries, including marine, aerospace, and civil engineering.3. Durability: The unique structural design of Triaxial Fiberglass Cloth makes it one of the most durable composite materials available on the market. It is resistant to wear and tear, corrosion, and other agents that can cause damage to other materials, making it ideal for long-term applications.4. Cost-effective: Due to its strength, durability, and other advantageous properties, Triaxial Fiberglass Cloth offers excellent value for money for projects where durability is paramount.5. Easy to Work with: Triaxial Fiberglass Cloth is effortless to work with, making it a popular choice for both amateur and professional fabricators.Given these advantages, it is no surprise that Triaxial Fiberglass Cloth is replacing traditional materials such as steel and aluminum, which can be considerably heavier and hinders fuel efficiency in applications such as aerospace and wind turbines.{Company name} is renowned for its products' quality and the wide range of industries they serve. The company is confident in the strength and durability of Triaxial Fiberglass Cloth, making it the perfect solution for various industrial needs. The company's Triaxial Fiberglass Cloth product line is continually improving, and the latest products now incorporate an improved weaving process to produce a more significant and high-density cloth. This development has added to the material's strength without reducing its flexibility or usability in any way.In conclusion, Triaxial Fiberglass Cloth is becoming a popular material for industries that require exceptional strength, durability, and reliability. It has several advantages over traditional materials such as steel and aluminum, making it a perfect solution for industrial applications. Companies like {Company name} have invested heavily in research and production of high-quality Triaxial Fiberglass Cloth, ensuring that their clients receive top-notch products that meet their unique needs and requirements. Contact {Company name} today and experience the functionality and superiority of Triaxial Fiberglass Cloth for your industrial applications.

Discover the Versatility and Benefits of Colored Fiberglass Cloth

Title: Innovations in Colored Fiberglass Cloth Unveiled by Prominent ManufacturerIntroduction:In recent decades, advancements in the field of textiles have opened up new possibilities for industries ranging from construction and automotive to aerospace and electronics. Among these innovations, colored fiberglass cloth has emerged as a pivotal material that combines functionality with aesthetics. Recognizing the growing demand for colored fiberglass cloth, the renowned manufacturer {} has introduced a groundbreaking range of products that promise to transform multiple industries. This article will delve into the unique characteristics of colored fiberglass cloth and explore the company's commitment to innovation.Understanding Colored Fiberglass Cloth:Fiberglass cloth is a woven material made from extremely fine and flexible glass fibers. Renowned for its high tensile strength, heat resistance, and durability, fiberglass cloth has long been an essential component in numerous industries. However, traditional fiberglass cloth is characteristically white or transparent, limiting its application in sectors where aesthetics play a vital role.Colored fiberglass cloth, on the other hand, offers a game-changing solution. By incorporating pigments into the manufacturing process, colored fiberglass cloth provides a visually appealing alternative while retaining the exceptional functional properties of traditional fiberglass cloth. This innovation opens up endless possibilities for architects, designers, and manufacturers to incorporate colored fiberglass cloth into their projects without compromising on strength and resilience.Product Offerings by {}:Leading the charge in the colored fiberglass cloth industry, {} has introduced an extensive range of products designed to meet the diverse needs of their clientele. The company offers colored fiberglass cloth in a wide variety of shades, ranging from vibrant hues to more muted tones, allowing for limitless creative expression.Furthermore, {} has developed a proprietary dyeing process that ensures the pigments are deeply embedded into the fabric, making them resistant to fading, wear, and exposure to various chemicals, ensuring a prolonged lifespan. This cutting-edge manufacturing technique demonstrates the company's commitment to providing the industry with a product that not only meets aesthetic expectations but also withstands rigorous environments and harsh conditions.Applications and Benefits:The introduction of colored fiberglass cloth by {} has far-reaching implications for multiple industries. The construction sector, for instance, can utilize colored fiberglass cloth in façade cladding, roofing, and interior decorations, enabling architects to complement a building's design while ensuring strength and durability. In the automotive industry, colored fiberglass cloth can be employed in interior trims, seat covers, and panels, enhancing the visual appeal of vehicles without compromising on safety or performance.Colored fiberglass cloth also finds application in the marine industry, as it can be used in boat hulls, sails, and furniture, seamlessly blending practicality with aesthetics. Additionally, the electronics industry can benefit from the incorporation of colored fiberglass cloth in the production of circuit boards, offering a visually appealing alternative to traditional non-colored substrates while maintaining electrical insulation properties.Conclusion:{}'s introduction of colored fiberglass cloth has created exciting opportunities for multiple industries, revolutionizing the way materials are used in both structural and decorative applications. With its exceptional functional properties and wide array of vivid colors, colored fiberglass cloth offers a seamless integration of aesthetics and durability. By combining creativity with cutting-edge manufacturing techniques, {} has paved the way for breakthroughs in sectors such as construction, automotive, marine, and electronics. As the demand for innovative materials continues to rise, colored fiberglass cloth promises to shape the future of industries where aesthetics and performance go hand in hand.

Types Of Fibreglass Cloth: A Guide to Different Materials Used in Fibreglass Fabric

In the ever-evolving world of construction and manufacturing, many companies search for materials that are both durable and easy to work with. Fibreglass cloth has become a popular option, offering an array of use cases in various industries.Fibreglass cloth is a type of textile material made from woven glass fibres. As a result of its composition, fibreglass cloth is incredibly durable and resistant to moisture, UV radiation, and chemicals. The strength of the material makes it a popular choice over other materials for application in marine and aeronautical industries.Although Fibreglass cloth is a relatively newer material, it has become a staple for many construction businesses and DIY enthusiasts. It is mostly used to build items such as boats, automotive parts, roofing materials, and even sporting equipment.One of the most significant advantages of fibreglass cloth is that it is available in various types, making it highly versatile. The difference in types is based on their weave pattern, thickness, and weight. The most common types of fibreglass cloth include plain weave, twill weave, and satin weave.Plain weave fibreglass cloth is commonly used to create lightweight panels or structures. The weave is relatively simple and features a checkerboard pattern. As the simplest type of fibreglass cloth, plain weave is easy to handle and provides a good finish as a base layer.Twill weave fibreglass cloth is a more complex weave that forms a diagonal pattern and is closely related to jeans material. This diagonal pattern provides additional strength and flexibility compared to plain weave, making it the perfect option for applications that require more intricate detailing.Finally, satin weave fibreglass cloth has a dense, tight weave that is ideal for creating high-performance parts. With the tightness of the weave, the cloth acquires higher flexibility and endurance, but it is harder to handle. The satin weave is common in applications such as automotive body kits or wind turbine blades.When it comes to buying fibreglass cloth, it is essential to consider the company's reputation. A renowned supplier should offer high-quality materials and reliable customer service. A long-standing provider in the industry is known for offering an array of high-quality fibreglass materials for any application.Their production process relies on the highest quality standards to ensure customers' satisfaction. They produce fibreglass cloth by using state-of-the-art equipment to ensure top quality and consistency of products.The company's team of experts is available to help guide customers in selecting the best fibreglass cloth for their specific needs. They offer assistance from design to installation, ensuring that each project meets the highest standards.To conclude, fibreglass cloth is an incredibly versatile material with a variety of use cases. Due to its excellent durability and strength, it is ideal for industrial applications such as aerospace, automotive, marine, and wind turbine manufacturing. Additionally, it is a material of choice for DIY enthusiasts and homeowners who use it for casting, laminating, and building projects. When searching for fibreglass cloth, it is essential to consider a trusted supplier known for its high-quality products and exceptional customer service.